Thanks to their scales, snakes can slither up to 14mph, squeeze into tight spaces, scale trees and swim. As a snake moves, its scales grip the ground and propel the body forward, this so-called friction-assisted locomotion is possible because of the shape and positioning of snake scales.

“There has been a lot of research in recent years into how to fabricate these kinds of morphable, stretchable structures,” said Ahmad Rafsanjani, a postdoctoral fellow at SEAS. “We have shown that kirigami principles can be integrated into soft robots to achieve locomotion in a way that is simpler, faster and cheaper than most previous techniques.”

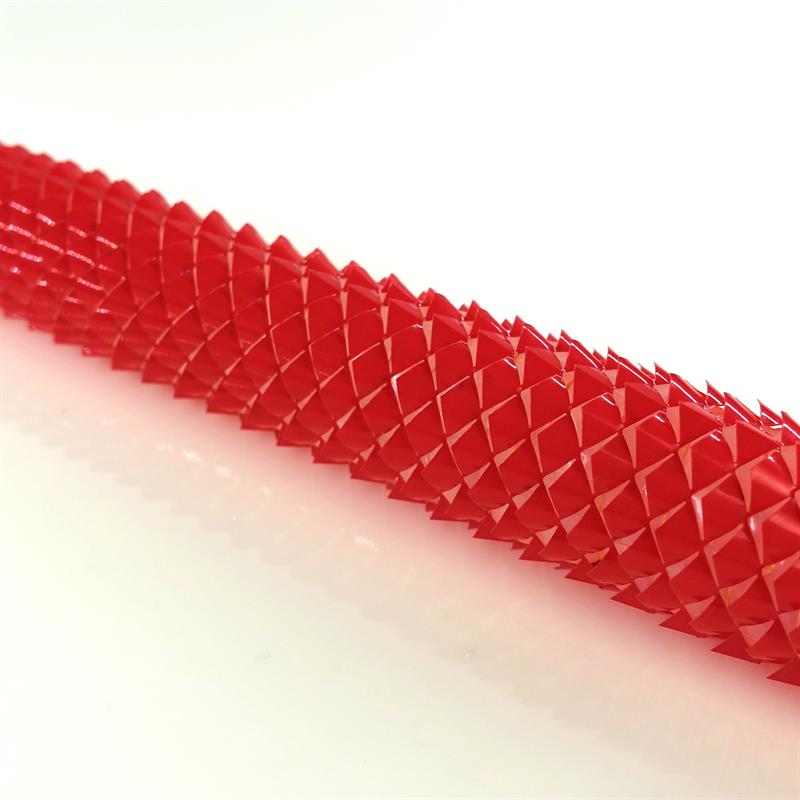

The researchers started with a simple, flat plastic sheet. Using a laser cutter, they embedded an array of centimeter-scale cuts, experimenting with different shapes and sizes. Once cut, the researchers wrapped the sheet around a tube-like elastomer actuator, which expands and contracts with air like a balloon.

When the actuator expands, the kirigami cuts pop-out, forming a rough surface that grips the ground. When the actuator deflates, the cuts fold flat, propelling the crawler forward.

When the actuator expands, the kirigami cuts pop-out, forming a rough surface that grips the ground. When the actuator deflates, the cuts fold flat, propelling the crawler forward.

The researchers built a fully untethered robot, with its integrated on-board control, sensing, actuation and power supply packed into its tail, and tested it crawling throughout the university campus.

The team experimented with various-shaped cuts, including triangular, circular and trapezoidal. They found that trapezoidal cuts — which most closely resemble the shape of snake scales —gave the robot a longer stride.

“We believe that our kirigami-based strategy opens avenues for the design of a new class of soft crawlers,” added Katia Bertoldi, Professor of Applied Mechanics.“These all-terrain soft robots could one day travel across difficult environments for exploration, inspection, monitoring and search and rescue missions or perform complex, laparoscopic medical procedures.”