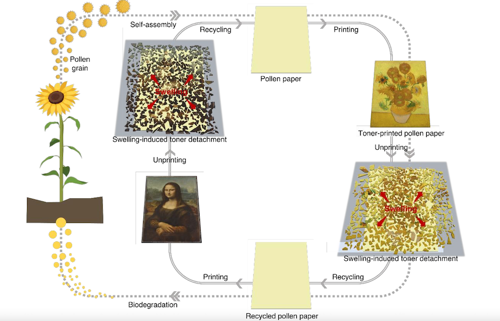

Described in Advanced Materials, the team’s research showed how high-resolution colour images could be printed on the non-allergenic pollen paper via laser printer, then ‘unprinted’ in an alkaline solution that removes the toner without damaging the paper. Testing showed the process could be repeated up to at least eight times, making the pollen-based paper a potential eco-friendly alternative to conventional paper, according to the researchers.

Led by professors Subra Suresh and Cho Nam-Joon, the team also believes the advance could reduce carbon emissions and energy usage associated with conventional paper recycling, which involves repulping, de-toning and reconstruction.

“This is a new approach to paper recycling – not just by making paper in a more sustainable way, but also by extending the lifespan of the paper so that we get the maximum value out of each piece of paper we produce,” said Prof Suresh, NTU president and senior author of the paper.

“The concepts established here, with further developments in scalable manufacturing, could be adapted and extended to produce other ‘directly printable’ paper-based products such as storage and shipping cartons and containers.”

Co-senior author Prof Cho Nam-Joon added that unlike wood-based conventional paper, pollen is generated in large amounts and naturally renewable. Making conventional paper, made of cellulose fibres found in wood, involves energy-intensive steps including logging, debarking sand chipping. This contributes to deforestation and rising CO2 emissions.

“In addition, by integrating conductive materials with the pollen paper, we could potentially use the material in soft electronics, green sensors, and generators to achieve advanced functions and properties,” Nam-Joon said.

According to the team, potassium hydroxide was first used to remove the cellular components encapsulated in tough sunflower pollen grains and turn them into soft microgel particles. This step removes the component in pollen that causes allergies.

They then used deionised water to remove unwanted particles from the resulting pollen microgel, before casting it into a 22cm x 22cm mould for air drying. This forms a piece of paper that is about 0.3mm thick.

Earlier research from the team showed that pollen paper can bend and curl in response to moisture in the air. To ‘stabilise’ the paper and render it insensitive to moisture, scientists said they immersed it in acetic acid.

To demonstrate printability, the NTU scientists printed a painting using a laser printer and found that the paper passed through the printer without damage.

While colours of the image on the pollen paper differed slightly from the same image on conventional paper, partly due to differences in subsequent treatments, scientists said the image resolution and clarity on both types of paper were comparable. They also found that immersion in water did not damage or soften the printed pollen paper.

‘Unprinting’, a concept involving removing toner from used paper before it is recycled, was also achieved by immersing the paper and rubbing it in a common alkaline lab reagent for two minutes.

The pollen-based paper swelled when immersed, causing the toner layer to mechanically disintegrate. The swollen paper was then left to shrink in ethanol for five minutes and air-dried. After treatment with acetic acid, the team said it was ready for printing again.

Conventional unprinting methods use chemicals that could pose environmental or health risks (e.g chloroform or acetone) to weaken the bond between the toner and paper, or high-intensity light to abate the toner. Both steps could damage the paper and render it unsuitable for reprinting, said researchers.

Aside from sunflower pollen, the NTU team found that pollen grains from camellia and lotus could also be used.