Researchers at the University of Cambridge are using practical techniques involving neutron reflectometry to make a breakthrough in the understanding of lubrication performance. The instrumentation required must deliver hair-width measurements, so the motion solution that drives it must be capable of the most precise level of control.

For vehicle engines, friction is a costly phenomenon. Friction causes wear that reduces engine life, but it also results in material breakdown that contributes to emissions. While governments impose emissions limits and car makers address materials and design, engine lubricant development remains crucial to combat the friction challenge.

Additive packages are formulated and added to engine oil, and typically comprise many different types of chemical compounds. The friction modification performance of these compounds varies dependent on the environmental conditions they face, and their effectiveness can also change according to the combination of compounds used. Because of this complexity, scientists haven’t yet been able to evaluate, at least in practical terms, how and why these additives work under real-world conditions.

“There’s been a lot of theoretical study, but a direct link between what makes a good friction modifier has not yet been found,” explains Beatrice Boggio Robutti, PhD researcher at the University of Cambridge, who is leading the study. “We don’t currently know why some additives are more successful, so the aim of the research is to take compounds that we already know have good friction performance, then study their behaviour to try and underpin the aspects that might be key in explaining why they are effective.”

By replicating a test with close to real-world conditions, the team hopes to understand why and how these friction modifiers are effective to improve their development.

Testing an organic friction modifier

Commonly, molecule compounds known as surfactants are used as friction modifiers by decreasing surface tension. To develop a practical test, the Cambridge team has selected a surfactant that has already demonstrated anti-friction and anti-wear properties under theoretical study. Importantly, surfactants can be derived from natural fats and oils. This creates an organic friction modifier, an economically viable option that is also a greener option.

Surfactants self-assemble into micelles, which are groups of individual surfactant molecules. The researchers wanted to test prior research suggesting that these micelles might adsorb – i.e. adhere to - metallic interfaces, which would make them valuable for friction reduction. Beatrice and her team initially assessed how the form of the micelles would impact adsorption and friction performance. But, to understand real-world conditions, it’s now critical to understand how this process changes between static and operating conditions.

To achieve this, the Cambridge team is using a technique known as neutron reflectometry, which involves firing neutrons at a buried interface between the micelle-containing solution and a metallic.

surface. By studying the reflection of neutrons off the interface, research can enhance the team’s understanding of the organic friction modifier’s behaviour.

Analysing shear rates

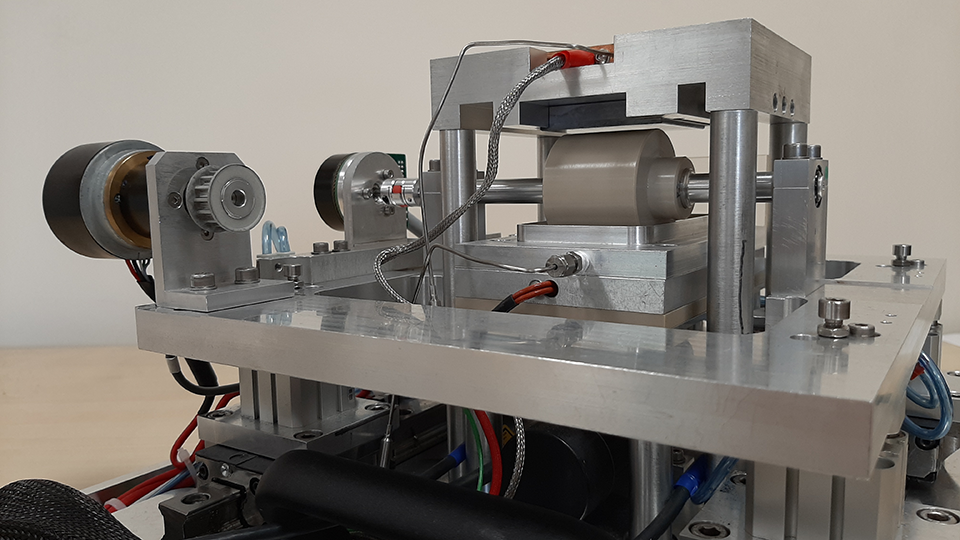

To analyse the shearing effect on the organic friction modifier, the team needed to replicate the conditions of an engine in motion. Infineum UK, the researchers’ industry sponsors, commissioned a custom-built tribometer, a machine typically used to measure friction, that would also integrate a neutron reflectometry environment.

The specially designed test apparatus involves a substrate made from a silicon block, sputter-coated with hematite, which acts as a substitute for an engine’s crank case surface - the researcher’s specific area of engine study. The device also incorporates a roller that can be moved towards the substrate at extremely close levels of proximity, down to the micron (one millionth of a meter, or 0.001 millimetres).

When the organic friction modifier solution is added to the tribometer's oil bath, the researchers start rotating the roller, controlling its speed and direction of motion to replicate the shear effect. By observing how the absorption of the organic friction modifier layer changes relative to the different proximities and speeds of the roller, the research team can determine the impact of various levels of shear.

Optimising control accuracy

The maximum shear rate across the engine reaches a maximum of around 10^6 (a million) Hz, so replicating conditions as close as possible to this level demands optimum precision. Although the original tribometer design could achieve micron-sized gaps, the Cambridge team needed even closer control to simulate virtual operating conditions.

The original configuration of the tribometer involved a belt drive, connecting the roller with the motor. However, the research team identified that this was a source of partial instability. This diminished control as oscillation of the roller caused it to hit the substrate at gaps below 200 microns. The risk of damaging the surface would not only require costly repair, but more crucially for the research team, it would mean downtime. As a result, the team couldn’t push the shear rates as far as they wanted towards real-world conditions.

“Laboratory time is extremely valuable,” says Beatrice. “Neutron reflectometry can take place only in designated central facilities, which for us involves travelling either to the ISIS Muon and Neutron Source in Oxfordshire, or to the Institut Laue-Langevin in Grenoble, France. Beamtime has to be applied for, with demand from numerous other research teams across the globe. We tend to have a maximum of 72 hours at a time to complete our study, meaning that the tribometer has to be functional 24 hours a day, in three-day bursts. Any downtime of the tribometer during beamtime would be a big problem.”

Motion redesign

To increase control precision and enable higher shear rates, the Cambridge researchers engaged with maxon’s engineering team for input on the redesign of the tribometer’s motion system. maxon Technical Engineer Ronak Samani specified a maxon EC45 flat, brushless DC motor with an integrated.

Hall sensor feedback device that would optimise position sensing. This new configuration would directly drive the tribometer’s roller with its speed managed by a maxon ESCON speed controller.

While research is ongoing, with the project culminating in September 2024, the motion upgrade means that Beatrice and team can now achieve much higher shear rates – approximately an order of magnitude higher than that previously attainable.

“Now, we can bring down the gap between the roller and the substrate down to 80 microns,” says Beatrice.

For perspective, that’s like reducing the gap from the diameter of a grain of sand down to little more than the width of a human hair.

Thanks to the control reliability of the maxon system, it can also maintain the roller’s set speed for test periods that typically last three hours.

“Ronak was really helpful in specifying the motion system for our requirements,” says Beatrice. “Even though some of the application parameters were initially unknown to us, Ronak was able to calculate the size and specification, providing the motor with the performance we needed. Following this, integration of the maxon motor was straightforward, and operation via the ESCON interface has been simple to achieve.”

Advancing knowledge of effective lubrication

Although the team’s research is ongoing, the precise results achieved so far in neutron reflectometry is already advancing the knowledge of surfactant performance as a friction modifier.

“Increasing the shear rate by such a leap meant that we can go a magnitude higher in our assessment of organic friction modifier films, which is really exciting for us,” says Beatrice. “Ultimately, this means greater understanding of the effectiveness of the surfactant to minimise friction and wear. This is crucial learning, not just for vehicles with combustion engines, but also to maintain the points of mechanical interaction on electric vehicles, or the transmission within renewable power generation applications.”

The PhD study has been supported by Professor Alex F. Routh, Academic PhD Supervisor, Department of Chemical Engineering and Biotechnology, University of Cambridge, as well as Industrial PhD supervisors, Professor Pete J. Dowding, and Oliver Delamore, both of Infineum UK Ltd.

To contact a maxon engineer, contact maxon on 01189 733337 or sales.uk@maxongroup.com.

Images © Science and Technology Facilities Council, The University of Cambridge.