A vessel landing at a wind turbine terminal.

Designing boat landings for offshore wind turbines involves accounting for heavy waves, the impact of 200-tonne maintenance vessels, worker safety and longevity. As a result, boat landings need to be strong, but building up strength is not as simple as adding steel: adding material to pieces without the right information to guide decisions would add unnecessary cost to the project. To this end, Wood Thilsted, a leading engineering consultancy firm specialising in offshore wind energy projects, incorporates structural analysis with automation into their design process. The team's lean workflow for creating, testing and validating designs is what allows them to turn around new boat landing designs in just a couple of months — and feel confident that they will last for 30 years.

Boat landings consist of ladders, fenders, pins and many other components, all of which need to be designed and tested in concert. "The challenge with the design is that we have a set of requirements with different load cases, and these are contradicting. I can spend a lot of time optimising one aspect of the design and then figure out that it does not work for another design case," said Louise Bendtsen, senior structural engineer at Wood Thilsted. "As a designer, this means that you need to have a broader perspective on the design as a whole."

The COMSOL Multiphysics® software helps Wood Thilsted take a holistic approach to evaluating the performance of its offshore boat landing designs. The design team uses this FEA software to model the governing load cases of any potential solution: the ultimate limit state (ULS) wave, representing the maximum peak forces that a boat landing is expected to experience throughout its projected lifespan, and the fatigue limit state (FLS) wave, representing the cumulative impact of 30 years of waves and crew transfers.

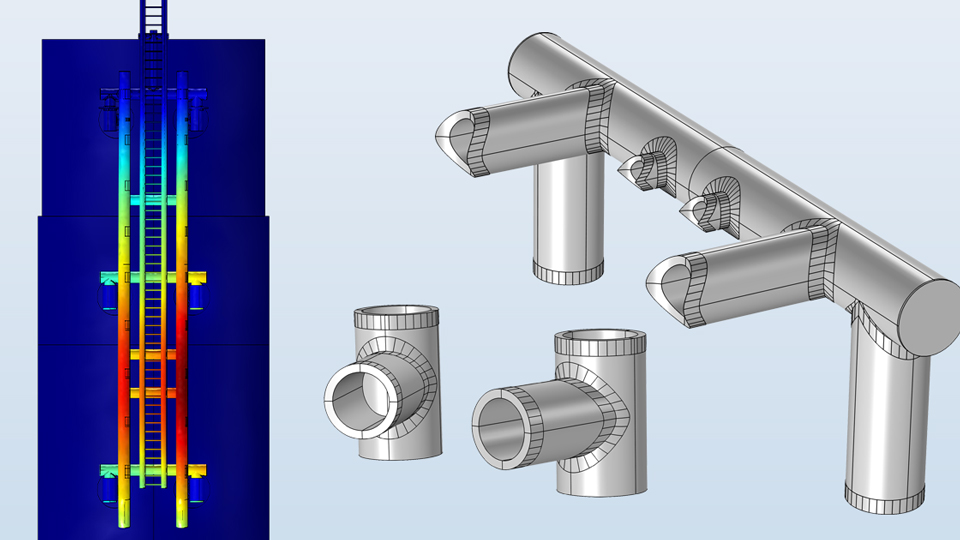

Simulation results visualising points of strain in a boat landing design (left) and custom model parts that can be reused in different projects (right).

"We are using COMSOL® to quickly and easily calculate what the stress concentration factors (SCFs) of our boat landings are and keep track of that throughout a project," said Bendtsen. To further validate potential designs, her team collaborates with Wood Thilsted's Primary Steel team for feedback on the SCFs and the limits of the materials being used. To automate processes such as applying loads, setting material properties, and choosing the analysis type, the team links the COMSOL Multiphysics software with the MATLAB® software.

"By using COMSOL Multiphysics, we get the stresses automatically, and then we connect this data to MATLAB using [the COMSOL add-on product] LiveLink™ for MATLAB®," said Bendtsen. "This allows us to write our own scripts that extract stresses and strains and perform all the results evaluations for the different load cases, freeing up time to improve the design and focus on its challenging parts."

Building up and storing information on particular parts means that the team can optimise and automate simulations for normal wave loads as well as unexpected vessel impacts. "There is a lot of opportunity for automation in the software, and that is really beneficial for us because we have all of these load cases that are similar but different," said Bendtsen.

A library of custom geometry parts saved in COMSOL Multiphysics allows Wood Thilsted to be efficient in its design approach. Using the software's functionality for reproducing the complex geometries of saved designs and making them parametric, the Wood Thilsted team is able to build new boat landing designs piece by piece, swapping out one portion of a design for another.

This approach also allows the team to choose from multiple configurations for each part, enabling them to change joint types and angles, for example. By making changes to a corresponding governing global geometry parameter, the team is thereby able to alter multiple similar parts simultaneously. As Bendtsen explains, "Our project teams are agile and fast. We can handle design changes in hours instead of weeks, producing the most steel-efficient designs at fast speeds."

Wood Thilsted's efficient boat landing design process is discussed in further detail in the COMSOL User Story Gallery.