Publicly unveiled for the first time on April 2 at the company’s R&D Centre in Neuwied, Germany, the AP family of adhesive tapes uses a specially-modified acrylic adhesive and has already found applications on some of Europe’s best-selling motor cars. Key models from Volkswagen Group, Skoda, Renault and Jaguar Land Rover are among these.

In a typical example of how DuploCOLL AP tape has drastically cut assembly times, while delivering in-service longevity, Lohmann points to the water management systems found in the tailgate or bootlid on both the estate and saloon versions of a well-known German model. Here, although the design and production engineering teams had agreed on the use of an intricate single-piece lightweight plastic moulded part to channel water appropriately when the tailgate or bootlid is lifted, they remained challenged by the mounting method.

After evaluating a variety of options, it was factory-cut precision die-cuts of Lohmann’s new DuploCOLL 96608 AP tape that won the day on the application. “In the final analysis, we were awarded the contract not just on technical bonding competence alone, but because we were the only supplier that recognised the advantages of adding finger lifts to each piece of tape the customer used in the assembly process,” says Lohmann’s automotive industry specialist Jeremy Parfitt. By adding these finger lift tabs, Lohmann engineers had provided the customer’s assembly-line operators with a section of tape that was easier – and therefore quicker – to fit with absolute accuracy every time. This was especially important, as the application required the channels to be mounted around a number of radii, some of them tight. “From a pure bonding viewpoint, the complete DuploCOLL AP tape range has been developed especially for such materials, so we were able to demonstrate exceptional strength in both shear and tension, as well as outstanding gap filling and sealing properties. And all these advantages were available in ready-to-fit precision die-cuts delivered direct to the point of production on the floor, if required,” says Parfitt.

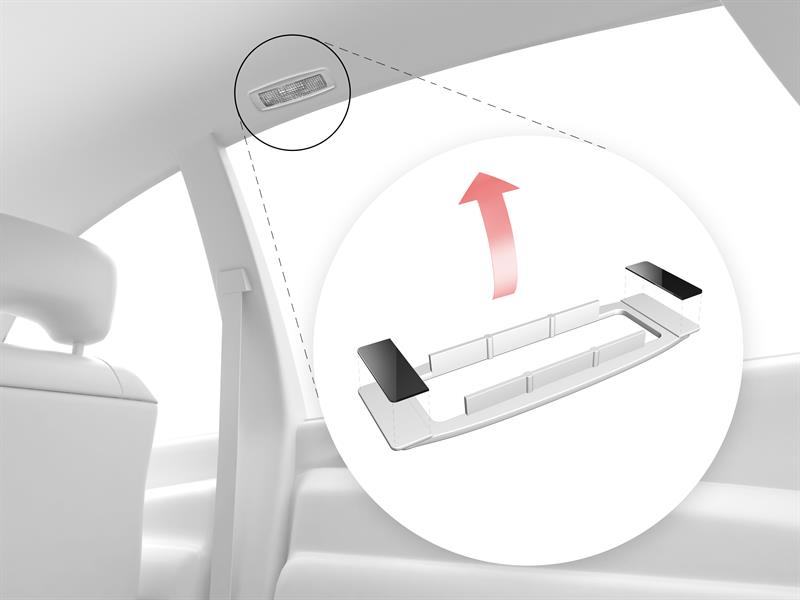

Lohmann states that another recent application success has seen a different vehicle manufacturer using DuploCOLL 97715 AP tape to bond courtesy lights direct to the headliner in a premium-brand luxury car. In this case, the tape won the contract partly because of an initial tack that allowed precise positioning and adjustment of the unit to be obtained, and also because the same tape could be used for both plastic-plastic and plastic-aluminium bonding. A permanent bond is quickly achieved at normal ambient temperatures without any special post-fitting treatment required. For this application, the customer was able to choose delivery of the precise amount of tape needed.

Other automotive OEMs are also using the new Lohmann range of AP tape in a variety of bonding applications: to mount aluminium kick plates into passenger door wells (DuploCOLL 97711AP); bonding plastic window trims into position (DuploCOLL 97715AP); and mounting parking sensors into the rear bumper of another best-selling vehicle (DuploCOLL 96608AP).

Drivers can also reflect on the advantages of Lohmann’s new tape when they take a peek into their wing mirrors on certain models of luxury car: here, DuploCOLL 373 bonds the mirror glass onto a heated backplate. In yet another example of exterior parts that are now being swiftly and permanently bonded using its new tape family, Lohmann points out that one of its automotive OEM customers is also using DuploCOLL 96608AP to bond the completed tailgate-mounted spoiler into place.

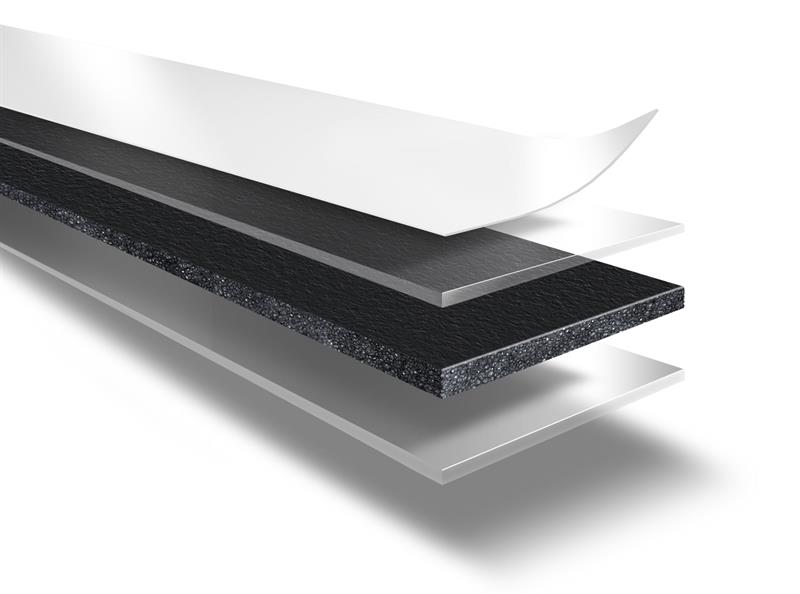

Dependent upon customer requirements, Lohmann confirms that the DuploCOLL AP range of bonding tapes can be supplied with a choice of either a paper or film liner, and that the range of AP tapes is available in a variety of thicknesses, including 0.45mm, 0.6mm, 0.8mm, 1.1mm and 1.5mm. No prior surface preparation treatment is required for any of the AP tape range. Lohmann’s R&D engineers have available a full set of detailed test result data covering its entire AP line-up. In the words of one lead engineer on a recent project: “The performance on common plastics used for add-on parts (on the open side of the adhesive) has proved perfect.”

Accompanying the arrival of the DuploCOLL AP range of tapes, Lohmann has also introduced another product, NP (New Paint). This has been designed and developed with a specific purpose in mind for automotive assembly applications. DuploCOLL 911XX is said to provide exceptional bonding strength, combined with high speed of assembly directly onto pre-coated panels and components.Lohmann says that DuploCOLL 911XX is ideal for bonding onto the most popularly used high-to-medium surface energy automotive paint systems specified by major OEMs. Included are those supplied by both PPG and BASF. Typical mounting applications in which DuploCOLL 911XX is designed to excel include bonding roof rails into place, mounting wheel arch trims, nameplates and a variety of other exterior trim parts to newly painted panels.

DuploCOLL 911XX is available with a choice of either a siliconised paper liner or yellow PE liner and may be specified in thicknesses (without liner) of 0.4mm, 0.6mm, 0.8mm, 1.1mm and 1.5mm to suit most applications. Interestingly, although developed explicitly for use on panels and components made from new-generation plastics, testing with a particular premium-brand automotive OEM has shown that the DuploCOLL NP tape range also delivers outstanding bond strength when used on a variety of common automotive substrates such as cold rolled steel, electrocoat and various plastic blends.