The recent trend towards using lightweight materials, such as aluminium and the mix of materials within vehicle body structures and sub systems, has now further complicated the issue. Add to that the increasing number of electrical features expected to be in vehicles for convenience and safety systems, and powertrain management, then the drive to find a more reliable and consistent solution is paramount.

A new solution tried and tested by many premium brand automotive manufacturers is the KSB nut and stud assembly from Profil Verbindungstechnik. According to the German company, it has taken some years to perfect the design to be suitable for use in automotive applications in both steel and aluminium.

How it works

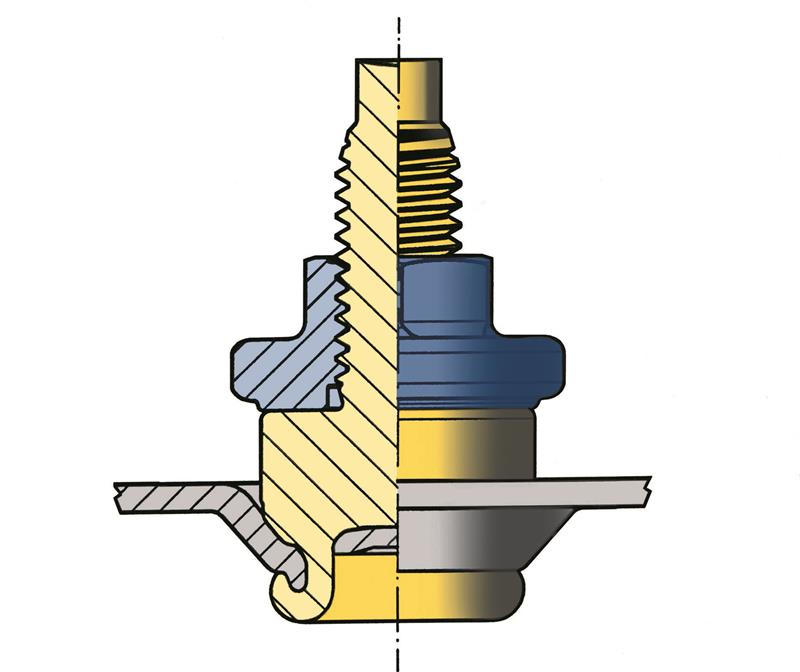

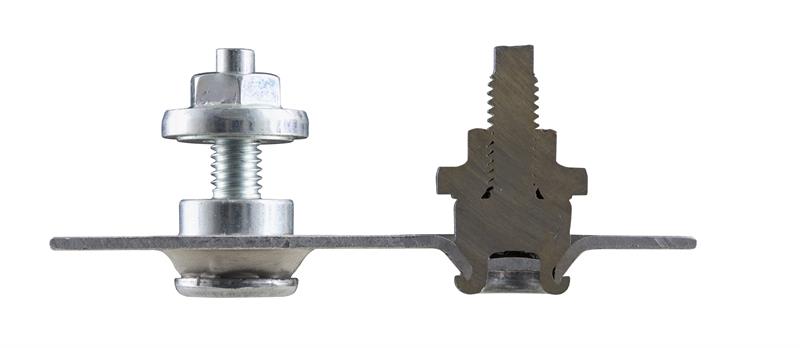

One of the clearest advantages of Profil grounding studs is that they are self-piercing. This means that each stud makes a neat hole through the sheet metal component. This technique provides a proper, clean metal to metal contact between the stud and the sheet metal part in thin sheet applications (0.7mm to 2.1mm).

An additional design is available for thicker materials (2.2 to 4.0mm), which is also self-piercing. However, this product does not pierce fully through the parent material. Furthermore, due to this specific riveting process, the connection point is rolled in. This characteristic means the connection point is protected against many external influences. As there is no sheet metal corrosion, there is no reduction in conductivity.

An additional design is available for thicker materials (2.2 to 4.0mm), which is also self-piercing. However, this product does not pierce fully through the parent material. Furthermore, due to this specific riveting process, the connection point is rolled in. This characteristic means the connection point is protected against many external influences. As there is no sheet metal corrosion, there is no reduction in conductivity.

During Profil’s manufacturing and assembly process, the nut is installed to a controlled torque figure and then, within the same assembly machine, a locking feature is created on the top face of the nut. This ensures two things: first, the nut cannot come loose during transportation, handling and installation into the sheet metal; secondly, the pre-applied torque ensures that there is no electro coat nor paint ingress between the faces of the nut and stud, ensuring a clean metallic surface is maintained, ready for cable shoe connection in the final assembly area and throughout the service life of the vehicle.

When the wiring cables are installed, the nut of the stud is disassembled, which presents a proper clean unpainted metallic contact face for cable shoes. The same nut is then re-used to secure the cable shoes and a good ground contact is assured.

Customer adoption

Validation tests of Profil’s grounding nut and stud assembly by major global OEMs have shown improved and more consistent conductivity, compared to the classical welding solutions, states the company. In addition, the Profil system is suitable for use in both steel sheet metal, steel sandwich materials and aluminium sheet metal, so for manufacturers such as JLR, which produces steel, aluminium and mixed metal (steel and aluminium combined) bodied vehicles, the Profil solution works for all applications.

The Profil nut and stud assembly is used on Jaguar XE, XF, F-pace and E-pace, as well as on Range Rover Velar, Land Rover Discovery and Discovery Sport. “It is now the default choice for grounding connections on all JLR products in both dry internal applications and also wet area applications,” says Profil. “Indeed, one could say that, given the off-road performance of JLR products, these are some of the most demanding applications in the automotive industry today.”

The Profil system has also been adopted by BMW, Porsche, Mercedes-Benz and Renault, especially in critical areas of vehicle bodies. Grounding studs solved the problem of grounding on steel sandwich material, as well as on aluminium structures. A good and consistent grounding system is essential to assure the functionality of all systems in vehicle electrical systems, from engine management through safety features such as air bags etc.

Another OEM uses the studs on the critical point around the fuel system. The OEM’s validation and corrosion tests are showing good conductivity, compared to classical welding solutions. There is especially an advantage with the increased use of lightweight materials, such as aluminium, where the installation of grounding studs by welding is increasing, due to the more complex welding process of aluminium.

One OEM that has changed to the Profil system has been able to reduce their average ground points per vehicle from 30 down to 22, which gives significant cost savings in inventory and process time, as well as being more environmentally friendly, reducing energy consumption, along with pollution and manufacturing carbon footprint.

The flanged nut of these studs has a special design to avoid any paint bleed in between the nut and the stud. The nut has a full metal prevailing torque feature, which prevents the nut dismounting itself. This ensures that, even in the most rigorous conditions, a good ground contact is maintained.

Reliability factor

The studs can be installed manually for low volume or prototype situations, or by fully automatic processes integrated into customer body assembly facilities. The various systems are already developed and have proven their reliability for customers for a long period of time, adds Profil.

The studs can be supplied with different surface coatings. Profil recommends a galvanic coating, which provides optimal installation performance. However, the specification can be defined in liaison with OEMs to remain in keeping with the car makers’ demands. Profil studs are already in place at some manufacturers operating in China.

The ongoing demands from the automotive Industry in general – driven by international legislative requirements to reduce CO2, while improving both passenger and pedestrian safety, moving towards lighter, but stronger, body assemblies and customer demands for more vehicle connectivity – are presenting many new challenges and opportunities to fastener suppliers in general. The Profil approach to use mechanical attachment techniques is geared specifically towards fulfilling those demands with new and innovative solutions, such as the KSB ground stud assembly.

Tech spec Profil grounding stud KSB0617A16A – objectives and specification

|