The company believes the technology employed allows the platform to be more than just the prototyping tool that many other 3D printing are, answering the market trend for short product life cycles and the demand for both the production of high-quality parts as one-off items and the personalisation of mass produced parts. Moreover, the system is based on processing qualified standard granulates; the Freeformer and the Arburg Plastic Freeforming (AKF) process.

"We see the introduction of the Freeformer as a huge technological step for our company,” says Arburg Ltd managing director, Colin Tirel. “We have always considered ourselves a technology innovator not a technology adopter and this is a superb example of this philosophy. It will enable us to offer our customers cutting edge technology which we can strategically align with our injection moulding and robot application technology portfolio to meet our customer's short and long term requirements".

Martin Neff, Technology Consultant for the Freeformer, said: “Freeformer will make plastic prototypes a thing of the past. A key feature is the use of standard granulate polymer at cost of Eu3 per kilo – the incumbent specialist material can cost Eu300 per kilo, providing a strong argument for this machine. And Freeformer requires little prior training.”

The Freeformer is the first additive manufacturing machine developed by a plastic injection moulding technology company, and answers the market trend for short product life cycles and the growing demand for both the production of high-quality parts as one-off items and the personalisation of mass produced plastics parts.

The Freeformer is one part of Arburg’s latest connected solutions for ‘Industry 4.0’. These digital technologies connect machines and products in an internet of the things in the Smart Factory, and will permit greater levels of mass customisation of parts in the future.

One Arburg Ltd customer, Bob Cook of Rotary Motion Technologies, commented: “Companies like ours need to respond to this because it is the way technology will go in the future – it is part of a trend for lightweighting, methods to reduce global warming, to produce parts efficiently and reduce development costs. At some point cars will be made completely from plastic components, including the engine, so additive manufacturing will have an important role and will have to scale up.”

Freeforming process

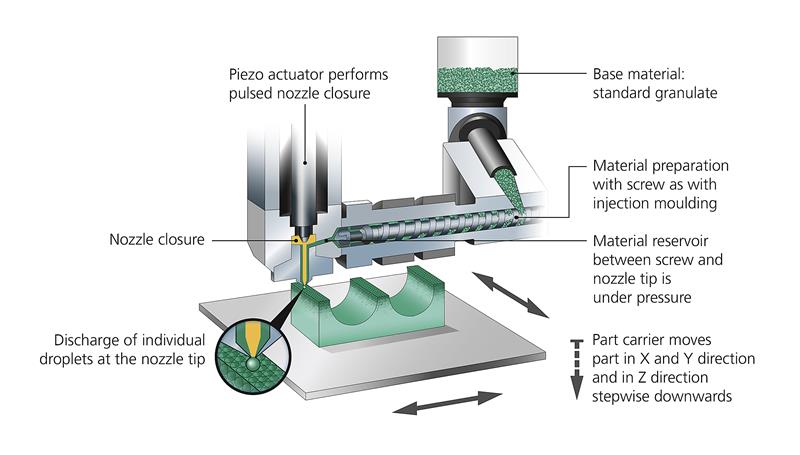

The patented Arburg Plastic Freeforming (APF) process has been purposefully developed to be more accessible to companies who are using plastics processes – specifically injection moulding. It does this by using a qualified standard polymer granulate that is far cheaper than some additive manufacturing materials, therefore bringing injection moulding material costs to additive manufacturing.

As with injection moulding, the granulate is first melted in a plasticising cylinder. A stationary discharge unit with a special nozzle then applies the plastic droplets layer-by-layer onto a movable part carrier using high-frequency piezo technology at a specified duty cycle of 60 to 200Hz. The droplets fuse together on cooling. The process allows uniform material displacement and creates strong, fully functional parts. The construction chamber of the Freeformer offers space for parts with maximum dimensions of 190 x 135 x 250mm. Depending on the nozzle used, the diameter of the plastic droplets generated under pressure is between 0.18 and 0.3 millimetres.

The Freeformer is equipped with a movable three-axis part carrier and two stationary discharge units as standard. The second discharge unit can be used for an additional component in order to, for example, produce a part in different colours, with special tactile qualities, or as a hard-soft combination. Where necessary, the Freeformer can build up structures from a special support material. This makes it possible to achieve unusual or complex part geometries. The supporting structures are subsequently removed in a water bath.

Currently unique in additive manufacturing is the combination of a standard elastic TPU material with reversible supporting structures. Possible applications include e.g. bellows, hoses, sleeves, or flexible parts for robotic grippers.

As an alternative, support can be built up in the same material as the part itself. A thinned out intermediate layer with specifically generated predetermined breaking points enables the supporting structure to simply be broken off mechanically at a later stage. This option is preferred for parts with free-standing structures and clearly defined edges.

The 3D CAD data for the parts being manufactured (STL files) are processed offline, special software generating the necessary manufacturing data via slicing. No special programming or processing knowledge is required.