Now translate that to your engineering task list. By simplifying the common tasks across your applications, you can reduce the total time you need to develop, deploy, and manage your engineering systems. In the proverbial climb to the top of the mountain for engineering systems, the four fundamental milestones are implementing core concepts, setting up the system, analysing data, and designing for the unknown.

Implement core engineering concepts

From the Nyquist sampling theory to the coefficients of a proportional integral derivative (PID) algorithm, accurately implementing foundational engineering concepts in your application is critical. But nowadays, knowledge of core engineering concepts is not enough. You must implement these concepts within the semantics of the tools and the programming constructs you are using to create custom logic.

From the Nyquist sampling theory to the coefficients of a proportional integral derivative (PID) algorithm, accurately implementing foundational engineering concepts in your application is critical. But nowadays, knowledge of core engineering concepts is not enough. You must implement these concepts within the semantics of the tools and the programming constructs you are using to create custom logic.

LabVIEW NXG introduces new nonprogramming workflows for measurement data acquisition, analysis, and visualization that complement the graphical dataflow programming paradigm native to LabVIEW. It simplifies the challenges brought on by using a new tool, coding software languages, and implementing engineering theory with a native learning system integrated in the environment. This learning system teaches all three of these aspects together in a single environment. For workspace orientation, the environment displays overlaid tips with contextual information during the first time you use these new capabilities. If you need an introduction to programming concepts such as loop structures, data types, or parallel process communication, LabVIEW NXG introduces them in a way that also familiarizes you with the environment.

For more information on how and why a concept is helpful, you can open one of the built-in interactive lessons. Each lesson features example code and workbooks that act as a guide through learning concepts with rich media content that explains the theory behind the code.

Set up your measurement system With a wide range of vendors developing instrumentation and sensors, you may find identifying and configuring the collective components in your system challenging. For example, consider the setup of a Histoindex Pte Ltd system, which was used to build a laser-based microscope for analyzing unstained biopsy samples. This PC-based system relied on five different subsystems containing four different instrument types, including a galvanometer, laser, and cameras.2 With a system like this, basic tasks such as discovering the hardware, installing the right driver, and configuring and verifying the setup can be frustratingly time-consuming.

With a wide range of vendors developing instrumentation and sensors, you may find identifying and configuring the collective components in your system challenging. For example, consider the setup of a Histoindex Pte Ltd system, which was used to build a laser-based microscope for analyzing unstained biopsy samples. This PC-based system relied on five different subsystems containing four different instrument types, including a galvanometer, laser, and cameras.2 With a system like this, basic tasks such as discovering the hardware, installing the right driver, and configuring and verifying the setup can be frustratingly time-consuming.

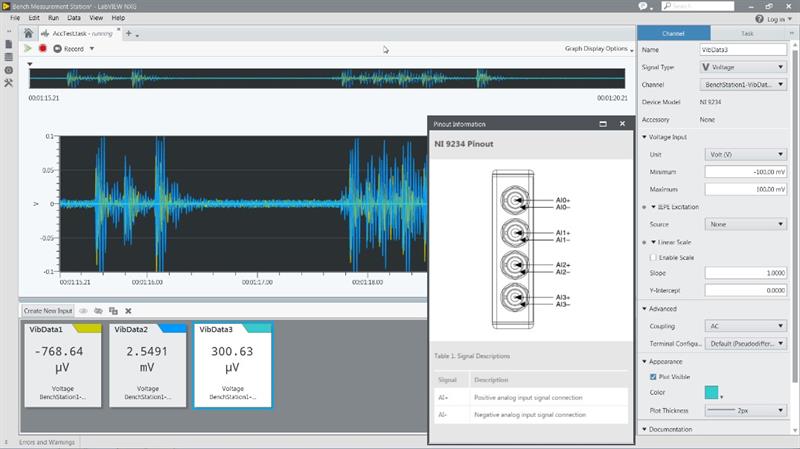

LabVIEW NXG provides interactive workflows to streamline these critical setup steps. By eliminating the need for programming, they can help you quickly validate your hardware configuration and view measurements with automatic discovery and driver identification, integrated documentation, and interactive soft front panels to instantly acquire and visualize signals.

By simplifying these time-consuming but important steps, you can instead focus on the specific details of the application you’re an expert in and add the most unique value.

Analyse measurement data

In the past, characterizing systems involved measuring only a few signals of similar sensor types, which provided more time for the subsequent analysis and report generation. Today, however, the number and diversity of the physical measurements you need to capture have dramatically increased.

For example, researchers at Instituto Hidráulico de Cantabria built a hydraulics research system that evolved to integrate a series of sensors including free surface movement sensors, strain gauges, ultrasonic distance measurement devices, and laser systems. With all these sensors and actuators, the researchers needed the ability to combine the captured data and synchronize the different events as they occurred for later analysis and extraction of results.

As measurement system complexity increases, engineers like those at Instituto Hidráulico de Cantabria ultimately have less time to gain insights from their measurements. In addition, tools traditionally used to help analyze signals are often fragmented, borrowed from other industries, and not optimized for the technical measurement, analysis, and system results that validation and test engineers need.

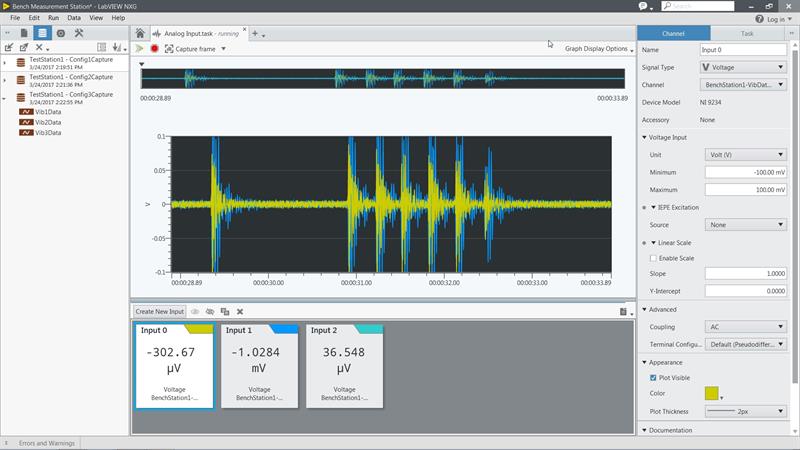

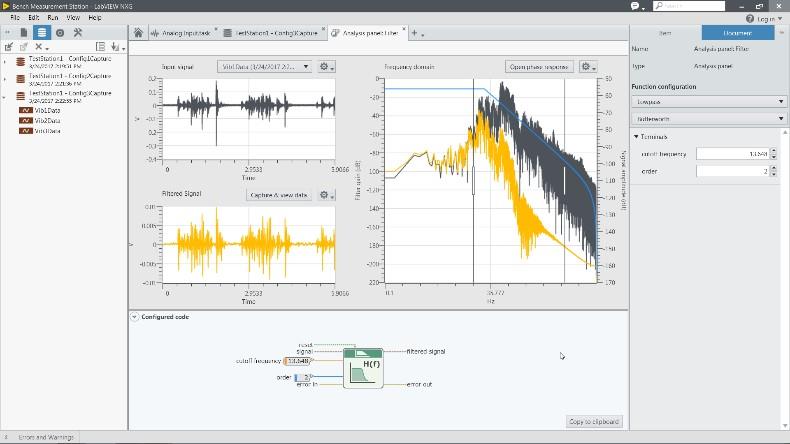

In the LabVIEW NXG development environment, the data you need to acquire, analyze, and visualize is always present, so you can maximize the use of the diverse sensor and actuator information engineering systems capture. This new experience is built on the philosophy that if you can see data, then you can capture it in a single click. The data includes signals, configurations, analysis results, inputs, and outputs—virtually everything in the environment. LabVIEW NXG then helps you collect these project captures in a centralized data management pane so you can easily manage your engineering data interactively.

From this data repository, you can rapidly explore your data using integrated data viewers to initially inspect your points of interest in the waveform. You can then interactively analyze the data with a single click on your region of interest to instantly visualize insights from the measurements. In addition, you can adjust parameters visually in real time to tune the analysis routine for your project requirements.

Design for the unknown

Though projects may begin with the promise of being common or routine, they can often evolve into something much more complicated. Engineers at Muc-Off Ltd experienced this firsthand as they built their measurement fixture for optimizing performance lubricants. The team needed to adjust the rig to deal with different sprockets, chain types, gear ratios, power expectancies, and speeds. Early iterations of the rig used fixed functionality measurement devices for data acquisition and control; however, this system struggled to keep up and simply did not have the customizability and hardware diversity to do the job in the tight timeframes required.4

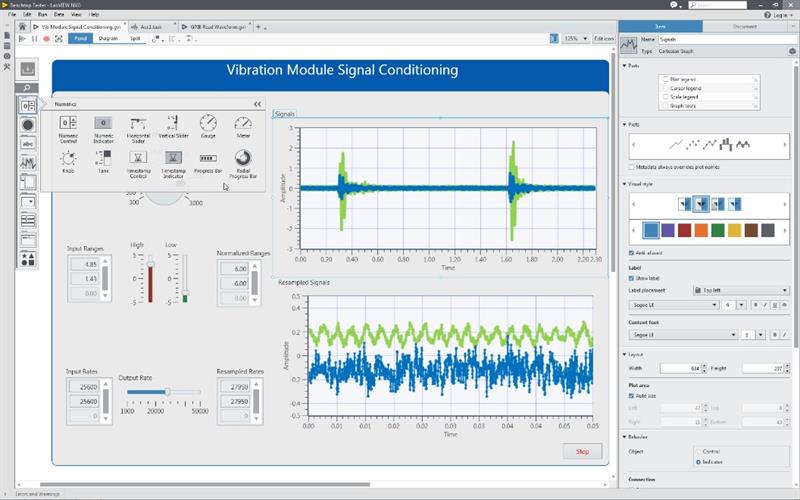

To combat this, LabVIEW NXG builds on NI’s software-centric platform, which includes modular hardware and an expansive ecosystem. This flexible and modular approach is designed to evolve with changing project requirements and is personified in the engineering workflows of LabVIEW NXG that help you transition from hardware setup, initial measurements, and analysis to an efficient development environment. This is important when customizing a test and measurement system as only you, the engineer, can. Throughout this transition to customization, you retain your engineering insight, configurations, and analysis routines. With LabVIEW NXG, you start at a higher level, and when you need more advanced analysis, logic, or automation, you can quickly build on top of the work you’ve already done.

Over the last 30 years, hundreds of thousands of engineers and scientists have used LabVIEW to increase their productivity through the abstraction of engineering tasks, and they have benefited from the intuitive functional view of graphical programming. LabVIEW NXG builds on this experience and combines engineering-specific optimizations of common development tasks to help you reduce system development time. From rapidly editing interactions like live wiring previews and editor zoom to building user interfaces with snap lines and new UI elements to using a unified debug probe window, you can take advantage of this development environment to create a professional engineering system in fewer clicks.

Get better results

Change is constant in engineering, and results help to drive faster, more innovative solutions. The only way you can embrace this faster pace is to address it with a different approach—one that’s tailored to engineers and scientists so they can focus on results. It’s an approach that gives you, today’s engineer, instant insight and the ability to rapidly iterate and speed past the obstacles that slow others down. With LabVIEW NXG, you can accelerate engineering and propel the world forward.

About the author: Jonah Paul is a senior software product manager at National Instruments (NI)