Intended to disrupt conventional manufacturing approaches, the advanced platform is being developed to combine the value of additive manufacturing with short-run metal parts production. The innovative technology is built to drive improved efficiency and cost savings using standard Powder Metallurgy (PM) alloys, mechanical properties with high accuracy and controlled shrinkage – as well as extremely fast throughput.

“We note that current approaches to 3D printing metal parts leave a lot to be desired – including slow post-processing, painstakingly intricate support removal, and hours of matching and grinding. Combined with the high cost of AM powders, this means each part is expensive, with a total cost of ownership that is too hard to justify,” said Rafie Grinvald, director of product marketing and management, Stratasys. “Our new platform is being designed to transform the current metals additive manufacturing landscape – presenting a viable alternative to typical production methods – and helping customers dramatically reduce the costs of creating reliable, consistent production-grade, metal parts for short-run applications.”

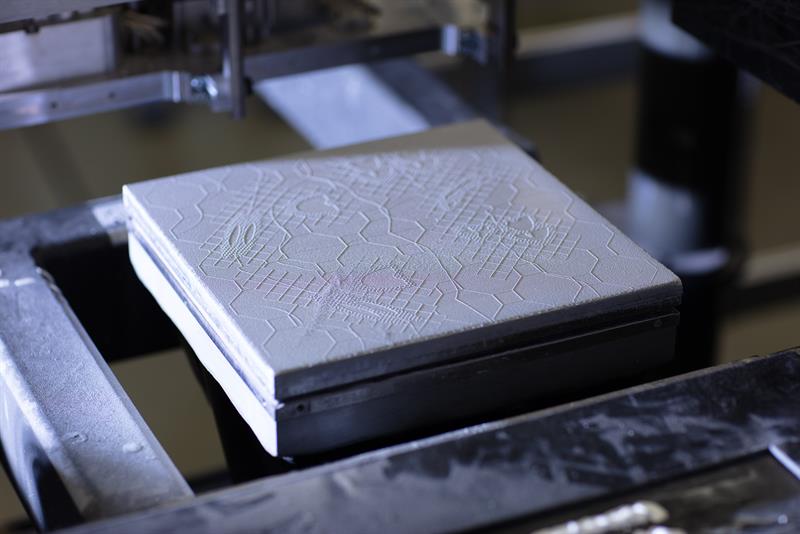

Developed internally over the past several years, Stratasys’ platform incorporates the company’s proprietary jetting technology and commonly-used powder metallurgy, starting with offering aluminium powders. The LPM solution includes a three-step additive manufacturing process combining traditional powder metallurgy with Stratasys’ PolyJet robust ink-jet technology. The process includes printing of boundaries with proprietary thermal ink, powder dispensing and spreading, and then compaction of the powder layer to achieve high-density and controllable shrinkage.

The end result is intended to be economically competitive vis-à-vis cost-per-part and throughput with easy to implement post-processing and extremely high part quality.

Stratasys is currently in closed-loop feedback discussions with OEMs and Tier-one suppliers on the new metals platform.

Away from metals, Stratasys is also bringing to market advanced elastomers and enhanced materials for its leading FDM and PolyJet machines. Enabling customers to make it today with 3D Printing, the FDM elastomer solution is intended to provide manufacturers with new levels of elasticity, durability with true soluble support – while advanced colours for PolyJet drive enhanced realism to transform legacy design and prototyping processes.

Empowering engineers with fast, accurate, and functional elastomers, customers can now produce parts with unique resilience – with an ability to greatly stretch or compress without losing shape. Offered across the F123 3D Printer platform and via North America’s leading service provider, Stratasys Direct Manufacturing, the Stratasys TPU 92A Elastomer is designed to meet the needs of manufacturers requiring high part elongation, superior toughness, and full design freedom. With hands-free soluble support, the solution can significantly reduce both production time and labour costs.

“Creating elastomer parts using traditional silicone or CNC molds are extremely costly and time-consuming – while it is our view that other additive techniques just cannot deliver parts with the size and complexity of our elastomer approach,” Zehavit Reisin, vice president and head of solutions and materials business, Stratasys. “Manufacturers demand 3D printing solutions that can be put to work in real prototyping and extreme production environments. With reliable and highly resilient parts, our solutions are designed to enable customers to do just that.”

“Creating elastomer parts using traditional silicone or CNC molds are extremely costly and time-consuming – while it is our view that other additive techniques just cannot deliver parts with the size and complexity of our elastomer approach,” Zehavit Reisin, vice president and head of solutions and materials business, Stratasys. “Manufacturers demand 3D printing solutions that can be put to work in real prototyping and extreme production environments. With reliable and highly resilient parts, our solutions are designed to enable customers to do just that.”

“The new Stratasys 92A is a compelling material for our consortium members because when combined with water soluble supports, it will provide them with the opportunity to produce medium to large, complex, durable and resilient elastomeric parts that were previously not feasible,” said Vince Anewenter, director of rapid prototyping consortium, Milwaukee School of Engineering.

Further advancing realism for 3D printed prototypes, Stratasys also announced a range of new materials for its J750 and J735 PolyJet 3D Printers. These enhancements include five new materials with an ability to mimic rubber, leather or plastic. These highly realistic prototypes are designed to enable teams to better meet specific design objectives, streamline iterations, and shorten time-to-market.

The Agilus30 White material can mirror such parts as rubber-like seals and gaskets for automakers – or vividly coloured models used for prototypes in sporting goods, consumer electronic components, or toys/figurines. Mixing both rigid and soft materials, Agilus30 White produces the widest range of life-like prototypes on a single printer. The newest member of the Agilus family of colours that includes translucent and black, Agilus White creates the highest levels of detail – critical for such industries as healthcare, where true white is necessary for such applications as medical devices.

VeroVivid Cyan expands the J750 and J735 gamut to more than half a million distinguishable colours – encompassing rigid to opaque, flexible and transparent. Producing vibrant colours and translucency in a single print, VeroVivid Cyan and the new VeroFlexVivid engineer effective, realistic prototypes for such markets as consumer goods, packaging, and eyewear. Supported by enhanced GrabCAD Print colour profiles, designers can actually “print what they see” with enhanced colour accuracy.

Delivering on previously announced roadmaps, Stratasys is also now making its PEKK-based FDM thermoplastic – Antero800NA – available on F900 3D Printers. This high-performance material is chemical resistant, possesses ultra-low outgassing properties, and exhibits high heat resistance.

MED625FLX is a bio-compatible material, well-suited for dental and orthodontic applications such as indirect bonding (IDB) trays and implantology case work ups. Now available on both Objet260 Dental and Objet260/500 Dental Selection 3D Printers, the material is designed to advance Indirect Bonding Trays by allowing the direct printing of flexible IDB trays and is built to enable orthodontists to reduce bracket placement times up to 75% and cut the cost for labs to produce by 40%.