In partnership with a leading manufacturer of gear transmissions for wind energy systems, NSK has developed double-row tapered roller bearings in a back-to-back arrangement for direct integration with planetary gears. Devoid of an outer ring, the interior of the individual planetary gear wheels is provided with a raceway for the rollers.

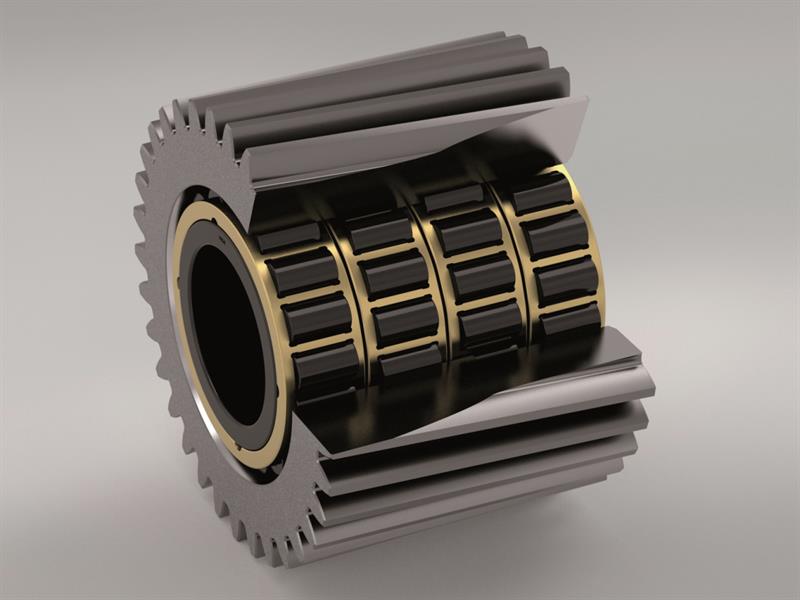

In a similar application for wind energy applications, four-row cylinder rolling bearings have been developed in place of conventional tapered roller bearings, again as integrated bearings without an outer ring. With four planets per stage, one set of bearings includes a total of 16 rows.

Key to developing bearings that are integrated with gears is precision during the manufacturing process. NSK bearing sets offered for such applications are therefore produced with tighter tolerances on the bore and envelope circle diameters of all bearing rows. At NSK, high precision manufacturing for wind systems following internal Wind Standard U 303 provides a decisive contribution to equal load distribution among the cylindrical rolling bearing rows, thus helping to deliver maximum service life.

Key to developing bearings that are integrated with gears is precision during the manufacturing process. NSK bearing sets offered for such applications are therefore produced with tighter tolerances on the bore and envelope circle diameters of all bearing rows. At NSK, high precision manufacturing for wind systems following internal Wind Standard U 303 provides a decisive contribution to equal load distribution among the cylindrical rolling bearing rows, thus helping to deliver maximum service life.