Over the years I have identified many studies which have investigated the safety of desktop 3D printing, for example, last year a study carried out by the University of California, Riverside (UCR) revealed that a number of 3D printers are highly toxic to zebrafish in nearby rivers. The Department of Civil, Architectural and Environmental Engineering at Illinois Institute of Technology in Chicago also found that the emission rates in one particular commercially available desktop printer were also harmful and associated with adverse health effects, including total and cardio-respiratory mortality, hospital admissions for stroke, and asthma symptoms.

These studies have shown that desktop 3D printers can emit large numbers of ultrafine particles (UFPs, particles less than 100nm) and some hazardous volatile organic compounds (VOCs) during printing, although very few filament and 3D printer combinations have been tested to date. However, in a recent edition of Environmental Science and Technology magazine there was a study outlined which quantifies emissions of UFPs and speciated VOCs from five commercially available filament extrusion desktops.

This research was carried out by the Department of Civil, Architectural and Environmental Engineering, Illinois Institute of Technology in Chicago, Ecole des Ingénieurs in Paris and the Department of Civil, Architectural and Environmental Engineering, The University of Texas at Austin, Texas.

It is well-known that both gases and particles are emitted during thermal processing of many thermoplastic materials. However, little is known about the types and magnitudes of emissions from desktop FFF 3D printers and how they vary according to filament material or printer characteristics. This study offers results from a screening analysis of potential exposure to these products in a typical small office environment.

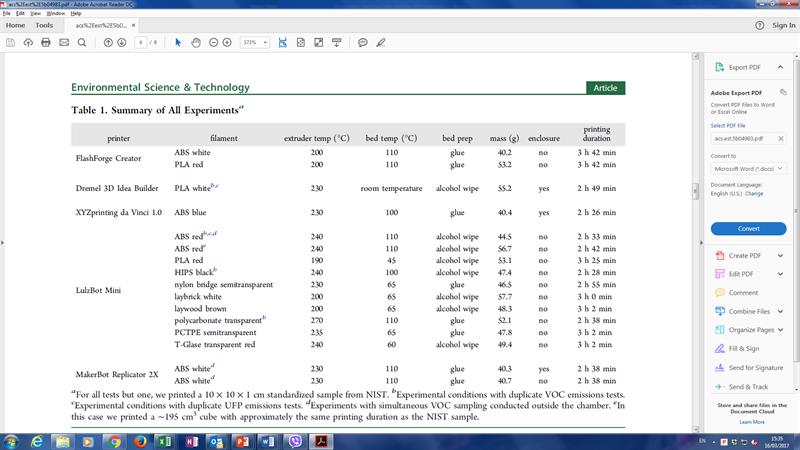

The study characterised UFP and VOC emissions from a total of 16 unique combinations of printers and filaments, including five popular commercially available makes and models of desktop 3D printers with up to nine different filament materials. The five printers included (1) a FlashForge Creator dual extruder model compatible with ABS and PLA (both filaments were tested); (2) a Dremel 3D Idea Builder compatible with PLA only; (3) an XYZprinting da Vinci 1.0 compatible with ABS only; (4) a MakerBot Replicator 2X compatible with ABS only; and (5) a LulzBot Mini that was compatible with many different types of filaments.

The study states the following -

“Measurements of UFP and individual VOC emission rates presented here have important implications for human exposure and health effects. For example, styrene, which is classified as a possible human carcinogen by the International Agency for Research on Cancer (IARC classification group 2B),23 was emitted in large amounts by all ABS filaments and the one HIPS filament. Caprolactam was also emitted in large amounts by four of the filaments: nylon, PCTPE, laybrick, and laywood. Although caprolactam is classified as probably not carcinogenic to humans,24 the California Office of Environmental Health Hazard Assessment (OEHHA) maintains acute, 8-h, and chronic reference exposure levels (RELs) of only 50, 7, and 2.2μg/m3, respectively.25 We are not aware of any relevant information regarding the inhalation toxicity of lactide, the primary individual VOC emitted from PLA filaments.”

Thus, the study recommends that manufacturers should work toward designing low-emitting filament materials and/or printing technologies. But in the absence of new low-emitting filaments, manufacturers should work to evaluate the effectiveness of sealed enclosures on both UFP and VOC emissions or to introduce combined gas and particle filtration systems. Until then, it is suggested that caution should be used when operating many printer and filament combinations in enclosed or poorly ventilated spaces or without the aid of gas and particle filtration systems. This is particularly true for both styrene- and nylon-based filaments, based on data from the relatively large sample of printers and filament combinations evaluated in the study.

Where does that leave us in our search for a safe desktop printer?

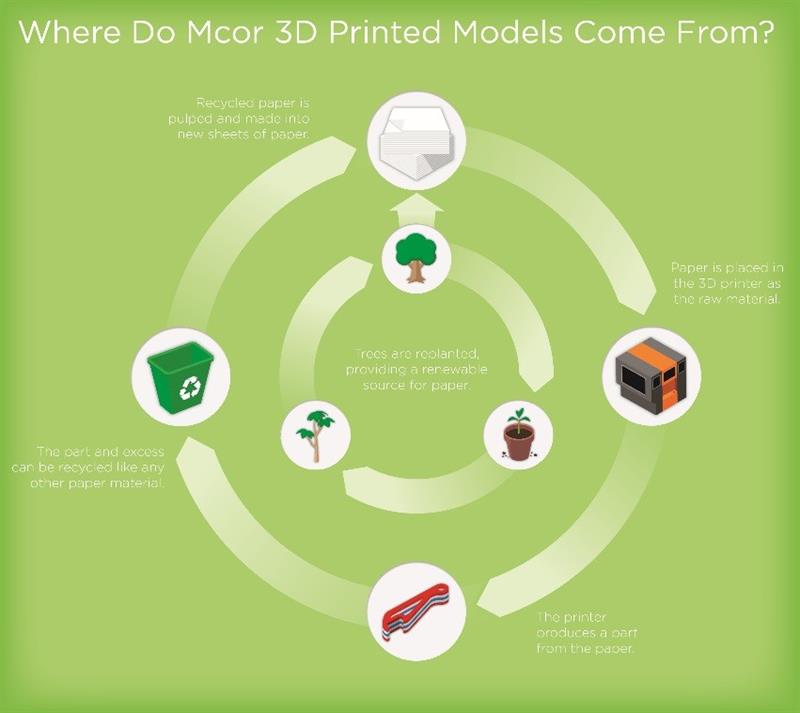

It is clear that there are issues with the materials outlined in this study however paper-based 3D printing poses no safety or health concerns. Mcor printers use paper as the build material rather than potentially toxic plastics, photopolymers and powders. They also use a water-based adhesive, similar to craft glue, in the process to bind the layers of paper so there are no fumes, toxic emissions or odours to worry about. Mcor printers allow users to toss printed models into the recycling bin for cradle-to-grave sustainability as illustrated in the infographic below.

And toxicity and emissions are also not an issue for Mcor’s most recently released printer, the Mcor ARKe, which uses a bio paper fully optimised for full colour eco-friendly 3D printing. This paper is also chlorine free, has an archival life of 200 years and bears the mark of responsible forestry. The other merits of using a safe, clean, eco-friendly material like paper is a technology that offers the industry’s highest-resolution colour at the lowest operating costs; Mcor’s SDL is between 10 to 20% the cost of any other 3D printing technology on the market!

So, it is no surprise that among the awards that Mcor have scooped over the years, the 3D Print Show awarded Mcor the Green Award in 2014, selected by the voting public.

In conclusion, there are lots of question marks over the safety of some of the desktop 3D printers on the market so if you are desperately seeking a safe desktop printer paper-based 3D printing might be the way to go.

Author profile:

Deirdre MacCormack is chief marketing officer at Mcor Technologies