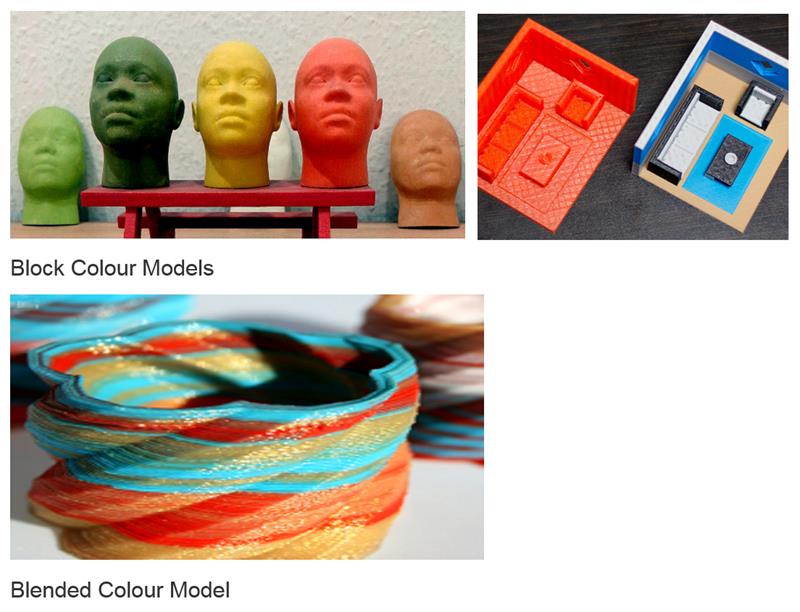

First of all, I will outline what is falsely termed ‘full colour’ and then I will let you know how you can easily identify a full colour model. There are a lot of printers on the market that are claiming full colour capability but in reality, they provide either block colour or blended colour. See below images that illustrate both types of colour:

With block colour, as the name suggests you simply get a block of colour either red, blue, green – whatever colour the filament comes in. Blended colour on the other hand attempts to blend colour in the process and you get a graduated colour from one colour to the next. However, neither are far from what you would call ‘full colour’.

So what is full colour 3D printing?

We have a simple method of testing if a 3D printer has full colour capability or not – we call it the ACAT (Any Colour Any Time) test. If the printer can print Any Colour Any Time on the build, then it is a full colour printer – anything less than this and it does not pass!

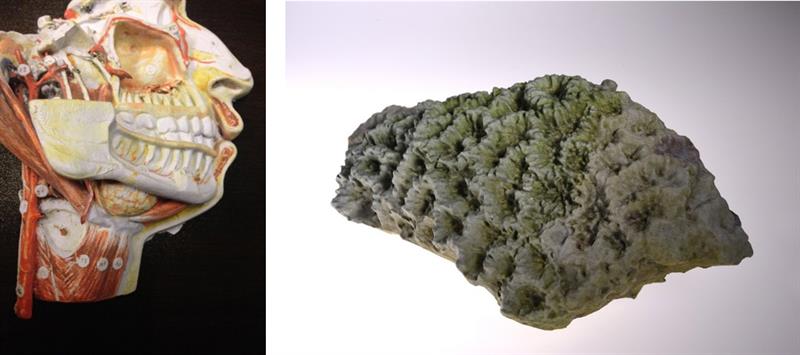

See in the images above - as the 3D printer makes the model and travels along the outer surface it needs to be able to change to any colour at any time on the build – this is especially evident when printing a human face – block or blended colour cannot provide the same result.

How do we do it?

Mcor employs a different technology from other 3D printing technologies to build colour models and therefore, the results achieved are also quite different.We use Mcor’s patented paper 3D printing technology using paper, CMYK ink, and water-based adhesive, to produce full colour 3D models. In many ways you could say that we are standing on the shoulders of the giants of full colour 2D printing – these companies have been printing ink on to paper for many years.

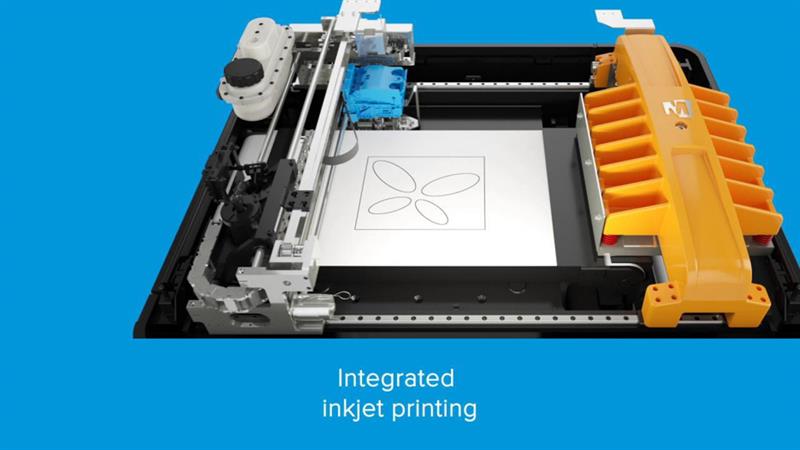

Our new printer, the Mcor ARKe uses an integrated inkjet head and can print 2 million colours measured. With a DPI of 4800 x 2400, this print head enables Mcor ARKe to exceed the DPI resolution of the highest comparable industrial 3D printer by a factor of 2x. So the DNA within Mcor’s technology has the potential to produce photorealistic 3D models.

Mcor ARKe 3D printer with integrated inkjet printing

Accurate Colour

Printing in full colour is one thing but printing in accurate colour is another. So with our colour technology not only do we strive to provide the largest number of colours for print but also the most accurate colour in the industry.

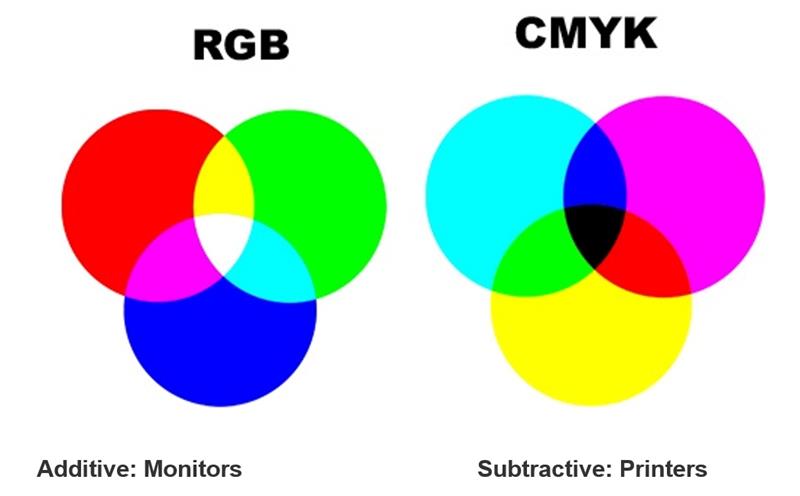

So the first challenge we have is the fact that the colour you see on your screen can differ greatly from the printer’s colours. A pixel on your screen is composed of Red, Green, and Blue (RGB) (primary “additive” colours), while our full colour 3D printer uses Cyan, Magenta, Yellow, and Key (Black) (“subtractive” colours). And you also need to keep in mind that different monitors display RGB differently, eg a Dell monitor will be different to a LG etc. So since there are two different colour systems at work here, we need a way to convert RGB to CMYK accurately.

With RGB you need to ‘add’ light to achieve your primary colours and all your digital data is usually in RGB format.With CMYK you must subtract white to make the colours accurate and this also applies to the colour in any 2D printer. Our goal is to convert a digital RGB file to CYMK so we can 3D print onto paper.

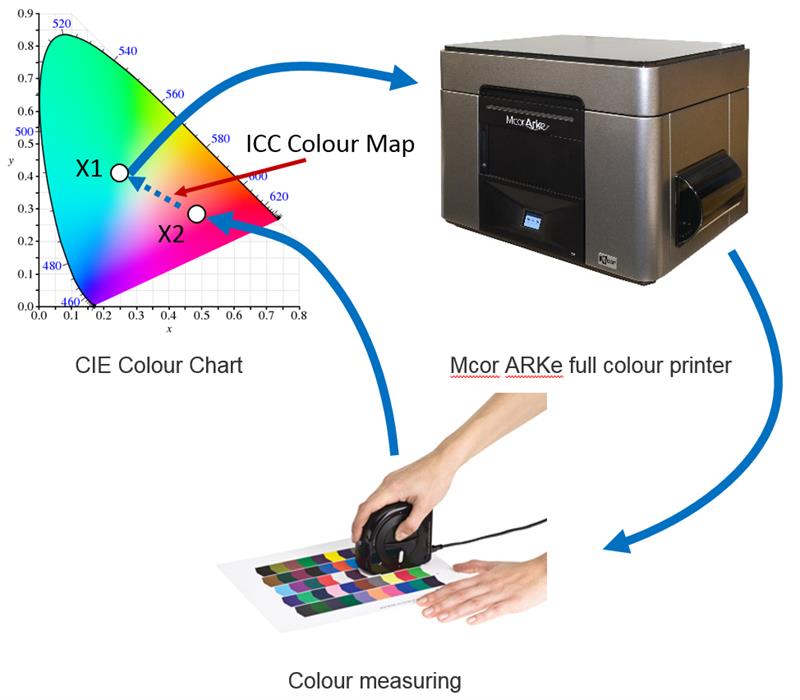

But how do we do this accurately whilst toggling between two colour systems. We have developed our own ICC colour mapping system which ensures what you see is what you get in colour terms. There is a once off set of steps to be taken to develop this ICC profile for your Mcor printer.

You start off with your source colour in your digital file and you look this up on the International Commission on Illumination (usually abbreviated CIE for its French name - Commission internationale de l'éclairage) which is the international authority on light, illumination, colour, and colour spaces. This identifies the exact theoretical colour in this digital file, X1. Then you print this out on your Mcor printer and using a colour measuring system you measure the colour – you will probably find this is not accurate to the original RGB colour in the digital file, see X2 in the diagram. Then we create the ICC profile that will pull X2 colour to the correct source colour on the digital file, X1.

The profile ensures that the 3D printer will precisely produce industry-standard colours as presented in a photographer’s, engineer’s or designer’s photograph, CAD model, scan or illustration. Without the ICC profile, 3D printers translate incoming colours to machine-specific ones, introducing unintended changes in the 3D printed colour along the way. Therefore, without the ICC profile there is no checking of the colours so ICC mapping acts like a closed loop system ensuring the printed colour is as close to the theoretical colour as possible.

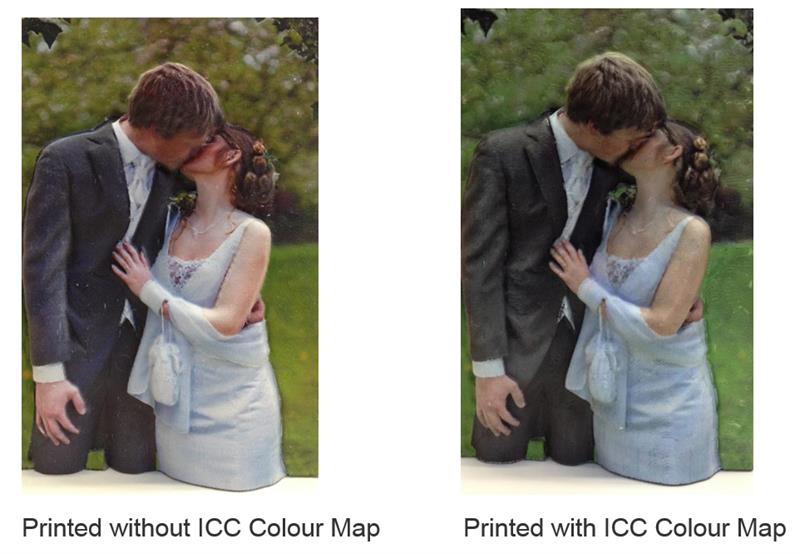

Here is an example of our ICC Colour Map at work on a model. The model on the left is printed without the ICC map and you can see the colour of the skin tones are quite red. But when the same model is printed with the ICC map the skin tones are printed correctly and more accurately to the colour in the file.

What is the value of Colour?

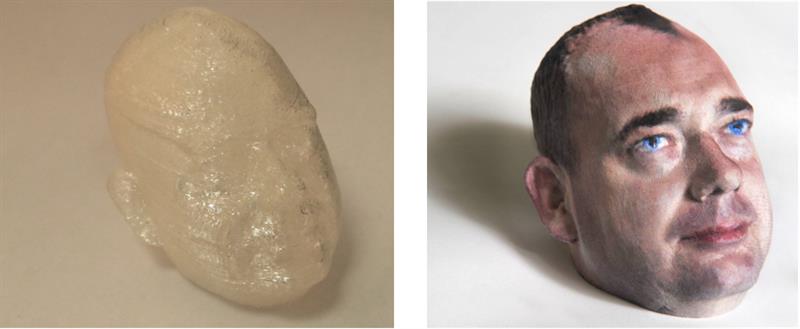

So you may ask yourself what is the value of colour, what’s the big deal? One of the easiest ways to demonstrate the value of colour is by showing the following two models

Both models have been printed from the same basic digital data, have the same geometry and but they look completely different. Adding colour to the file just adds a completely different level of detail even though the geometry is exactly the same. The human eye picks up this detail including textures and contours and makes the model super realistic. We have evolved to see in colour so we automatically pick up the extra detail that full colour offers.

But why does it matter?

I would say that it matters a lot, to a lot of different markets. And now that low cost high quality full colour 3D printing is accessible this has identified many groups to whom it is essential.

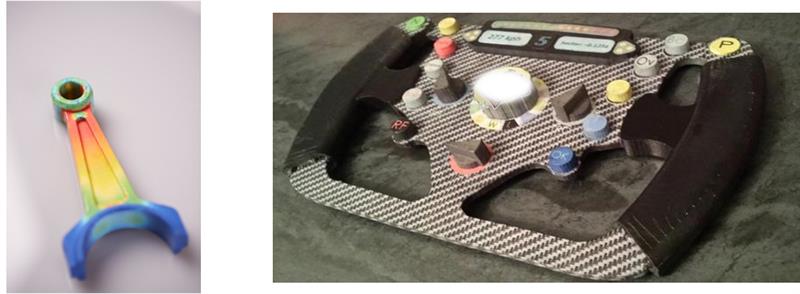

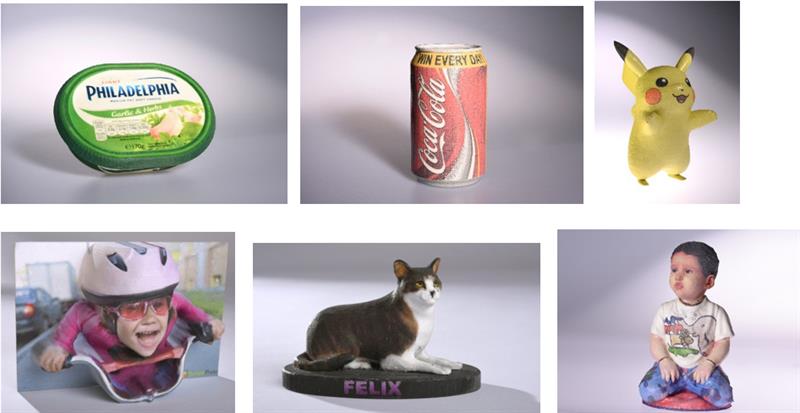

You can 3D print a design or engineering label or logo right onto your model instead of painstakingly painting it on later, or worse, doing without it.

Teachers can bring finite element, heat and solar analyses off the screen, and into their students’ hands for greater understanding and learning. And even parts of a machine assembly for greatly enhanced communication.

You can easily distinguish anatomical parts to prepare for a complex surgical procedure resulting in reduced patient time under anaesthesia and a better surgical results.And more recently we have identified another application in the area of marine life which requires colour – to help illustrate coral bleaching and destruction to marine life and so increase awareness to the issue.

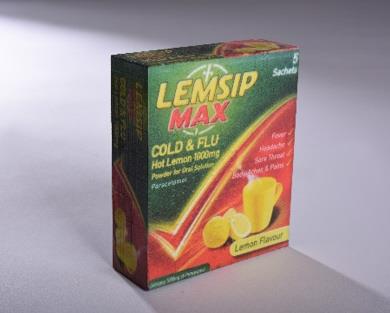

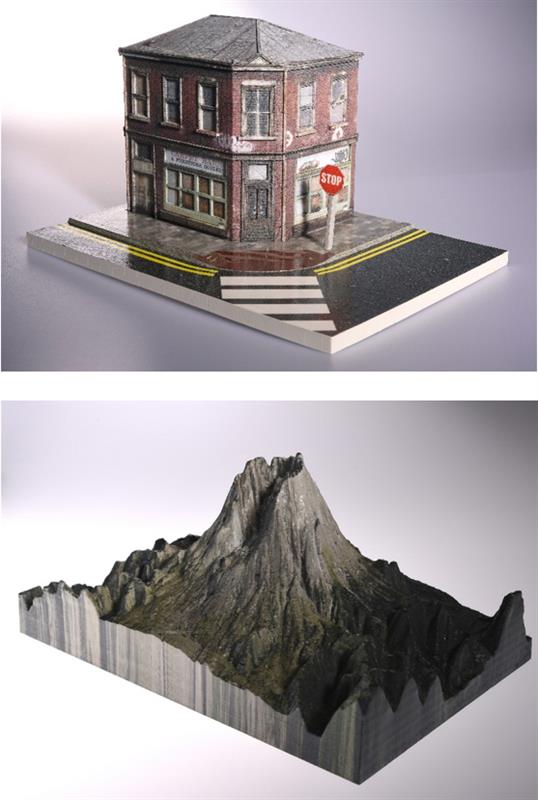

You can print texture maps (images, photos, shadows, bricks and trees, and other details) onto your model so that it looks just like the real-life object. You can use the realistic models for marketing, sales, client presentations, and detailed design testing. GIS mapping is another area where colour simply transforms the information on the model and enhances it to no end.

Suddenly a whole host of artistic, packaging, animation and customised consumer products and applications are available to you – things you can now do with colour that you simply can’t do with a monochrome 3D printed model.

New businesses and revenue streams are now possible and as we move closer to consumer 3D printing applications, colour will become more and more relevant. Long gone are the days of black and white TV, the consumer will demand full colour models of high quality.

So next time you hear a claim for ‘full colour’ 3D printing use the ACAT test to see if the technology qualifies as ‘full colour’. You will never again mistake blended or block colour for ‘full colour’.And be sure that full colour 3D printing does matter and we will see more and more industries coming to it in the coming years.

Author profile:

Deidre MacCormack is chief marketing officer at Mcor Technologies