Currently, VR user interfaces consist of remote-like devices that vibrate when a user touches a virtual surface or object.

“They’re not realistic,” said Jurgen Schulze, a researcher at the Qualcomm Institute at UC San Diego. “You can't touch anything, or feel resistance when you’re pushing a button. By contrast, we are trying to make the user feel like they're in the actual environment from a tactile point of view.”

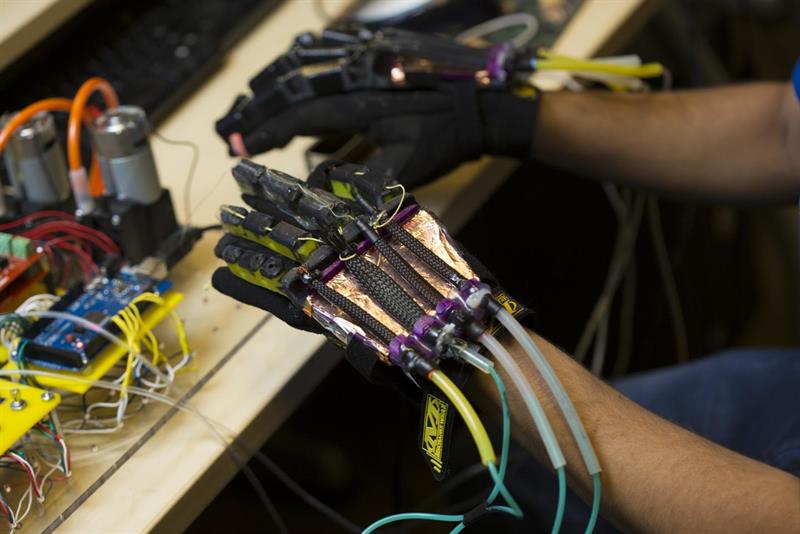

Previous work on gloves as VR interfaces have produced bulky products made from heavy materials, such as metal. The gloves the UC San Diego engineers have developed has a soft exoskeleton equipped with soft robotic muscles that make it much lighter and easier to use.

The system involves three main components: A Leap Motion sensor that detects the position and movement of the user’s hands; a custom fluidic control board that controls the gloves’ movements; and soft robotic components in the glove that individually inflate or deflate to mimic the forces that the user would encounter in the VR environment.

One key element in the gloves’ design is a type of soft robotic component called a McKibben muscle, essentially latex chambers covered with braided fibres. The muscles respond like springs to apply force when the user moves their fingers. The board controls the muscles by inflating and deflating them.

One key element in the gloves’ design is a type of soft robotic component called a McKibben muscle, essentially latex chambers covered with braided fibres. The muscles respond like springs to apply force when the user moves their fingers. The board controls the muscles by inflating and deflating them.

Researchers 3D-printed a mould to make the gloves’ soft exoskeleton. They say this will make the devices easier to manufacture and suitable for mass production. The researchers used silicone rubber for the exoskeleton, with Velcro straps embedded at the joints.

Engineers conducted an informal pilot study of 15 users, including two VR interface experts, playing the piano in VR. They all agreed that the gloves increased the immersive experience.

The engineers are working on making the glove cheaper, less bulky and more portable. They also would like to bypass the Leap Motion device altogether to make system more compact for use in areas like video games and surgery.