PROFINET has now become standard for many users in a wide variety of industries, as reliable systems and innovative machines are only possible with powerful communication. Apart from the high speed and safety-related requirements, a growing number of additional functions are necessary to achieve the higher levels of productivity, quality and availability needed in global competition. On top of this, there is an ever-increasing demand for future-proof solutions so benefits can be gained today from possible future innovations.

System architects of PROFINET (PN) have consistently exploited the additional possibilities of Ethernet, as compared to fieldbus concepts. In this way, simply by switching from fieldbus systems to Ethernet, shorter cycle times for the IO data are achieved due to the 100 Mb and full-duplex transmission. Using dynamic frame packing (DFP), a mechanism available in PROFINET, and automatic fragmentation of TCP/IP data, update rates of 31.25 µs are possible with open TCP/IP communication. However, the update rate of 250 µs available with PROFINET, combined with isochronous real-time communication (IRT) with a maximum jitter of 1 µs, provides far greater speed than is actually needed for most applications. The usual cycle times of controllers, IO modules or drives are many times higher and, as a rule, the deterministic requirements are of more importance in this respect.

Devices with more than just IO communication

By integrating the PN protocol device designers can make new, built-in options, e.g. the partial shutdown of energy consumers during breaks in production, readily accessible to their customers. Without consistent standardisation, only manufacturer-specific solutions with their own program blocks are possible, which makes use unnecessarily complex.

Engineering via PROFINET is easy. For example, all language and device versions of a device family can be described by means of a single general station description (GSD) file, and the most common faults are defined by means of the PN standard. This simplifies handling for the developer of the GSD and for the user during commissioning.

The properties of PROFINET, such as the simple addressing of devices with names and the integrated topology view, directly facilitate engineering and commissioning.

The properties of PROFINET, such as the simple addressing of devices with names and the integrated topology view, directly facilitate engineering and commissioning.

This topology view not only serves as plant documentation, but – combined with the diagnostic messages – also offers reporting of faults with their precise location, allowing them to be resolved more quickly and easily. Access here is not only possible locally by means of PLC or engineering, but also via add-on tools or remote access. A wireless communication route is favoured, as this mobility enables commissioning engineers to position themselves and their engineering PC at a location that offers the best view of the machine.

Devices that only require one channel of TCP/IP communication, such as cameras or IO devices with additional quality data, can easily be connected using wireless or cable communication. The function of generating quality data or additional associated values is increasingly spreading into the devices, as the rapid advances in performance of industrial electronics hardware and software enable corresponding devices to be developed at commercially competitive costs. Here are some of the options for different development platforms.

Standard Ethernet controllers

Through the integration of a PROFINET protocol stack, an existing industrial electronic system that already has an Ethernet controller ‘on board’ can be extended to include PN functions. No additional hardware is necessary. Although this does not enable any synchronised motion applications to be performed, it does allow the most widely used real-time requirements up to 1 ms to be implemented. A simple example or ‘playground’ for such integration is a PN device or controller on a Raspberry Pi or BeagleBone Black.

PROFINET protocol ASICs

Many will be familiar with specific protocol ASICs from fieldbus technology e.g. SPC3 for PROFIBUS or SUPI for Interbus. The same solutions are, of course, also available for PROFINET integration. Protocol processing, including the optional IRT synchronisation, takes place on a specific ASIC. The PHY for controlling the Ethernet hardware interface and two ports for the line integration are integrated.

FPGAs

Flexible PN integration with integrated pre-processing is available with FPGAs. Fully tested IP cores are available for the different requirements - including IRT communication - for integration into an overall device. Thanks to the FPGA technology, fast adaptations to customer requirements are possible without any hardware redesigns.

Hardware chips with PN support

Thanks to the high performance of the electronics, hardware chips that combine both PN protocol processing and application processing in hardware and firmware are becoming more widely used. In comparison with a multiprocessor solution, this reduces the number of components and the expense and effort of coordination.

Modules

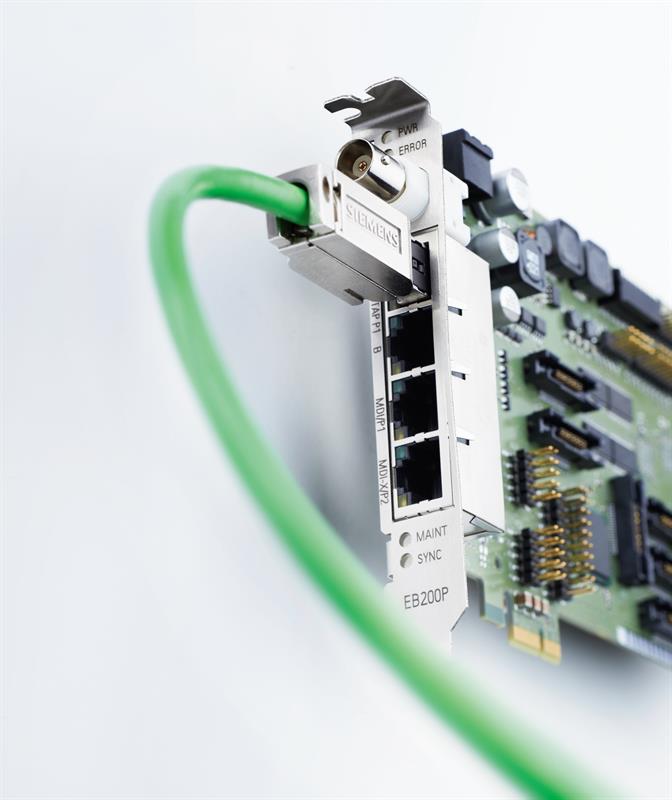

Even in the fieldbus era, plug-in modules which, like protocol ASICs, offer a defined application interface, proved their worth. No hardware development is necessary here if the interface is already available. To enable PC integration, however, the interface modules are also available for connectors that are optimised to smaller dimensions.

Gateways

Particularly where smaller quantities are concerned, gateways are used which convert other serial protocols to PROFINET.

Of course, these different platforms are used not only during development of a PN device, but also when integrating a PN controller into PLCs, PCs or other automation systems.

The possibilities of integration listed here require varying stages of hardware/firmware integration and thus different proportions of in-house development by the device manufacturers. In this way, not only the time required for familiarisation and the utilisation level in the companies can be controlled, but also the device costs that depend on the quantities manufactured.

Choice means optimisation

Selection of the right integration platform, and of the appropriate scope of functions of the respective PROFINET device to suit the customer, demands rather more consideration during development than if a communication architecture only permitted a few platforms or only restricted services.

However, this is the only way to create devices that are optimised in terms of both functionality and cost, which enable the manufacturer to integrate unique selling points that bring further benefits for the end user.

Technology providers naturally provide support for this selection on the basis of requirements and boundary conditions of a device manufacturer. For the integration of the PROFIdrive drive profile, source code is available on both the device and controller side, thanks to the work of the PROFIdrive community. This facilitates implementation in motion control devices, numerical controllers and robots. With its different application classes, PROFIdrive covers all applications, from simple rotary speed axes to interpolated isochronous mode multi-axis applications. The user benefits from the standardised application interface used by different manufacturers.

Unfortunately, some extended options of PROFINET are still not used by all device manufacturers, as they only want to offer functions used together with other types of communication. Further development is possible at any time, however, and is often only a matter of time.

However, the PI community can tackle more extensive innovations, such as those to be expected in the context of Industry 4.0, on the basis of the existing openness toward additional communication on the same cable, and the high level of standardisation of the data types. The 100% compliance with IEEE and thus with the Ethernet standard gives PROFINET a first-class starting point from which to face the future as, especially in the field of real-time Ethernet, many innovations are to be expected in the future from which PROFINET users will also benefit. The commitment of the many manufacturers and the market penetration of PROFINET are encouraging the continuous development of communication functions and thus the crucial added value of the devices for customers' plants and machines.

PROFIBUS and PROFINET

|

Author profile:

Mark Freeman is product manager – Distributed I/O and Failsafe Products at Siemens UK & Ireland