Additive manufacturing is now regarded as a technology that most of us are familiar with. But it is not really a single technology; more of a set of technologies with different levels of relevance for different circumstances. Some of these technologies are more embedded than others, although still mostly in a prototyping environment. But the technology required to produce realistic colour 3D models has been noticeably lagging.

Part of the reason for this is down to the lack of suitable 3D printing equipment and partly, according to John Gould, Stratasys president, North America: “To really mass adopt 3D printing we have to simplify the workflow. Today 3D printing is still too complex. Many times you need to be a CAD engineer to really understand the end to end workflow, and many choose to not adopt.”

He described a workflow to get from an idea to 3D printed object which involves a conceptual drawing being passed to a CAD engineer, who then passes engineering drawings as STL files. These in turn may need to be adapted for the particular printer or printers if there are multiple materials and colours, and after printing the parts, those parts may need to be post-processed – cleaned and smoothed – before going to a paint shop. While this obviously takes in every possible step in a complex process, it makes the point that colour 3D printing is not straightforward. That is, until now, claims Gould.

Reducing this process to a two stage procedure – design and print – has come about due to a software development forged by Stratasys and Adobe. The result is Stratasys Creative Colours powered by Adobe's 3-D colour print engine.

“What we're able to do is to take Adobe's understanding of how these three colours can be mixed,” explained Mike Scrutton, director of product development for 3D printing at Adobe.“The change effectively with the new software is rather than somebody having to pick one colour effectively from a swatch of 46, you can now 3D paint in an application like Photoshop, in any colour you like.”

What helps is that Stratasys has introduced a couple of new materials - Vero PureWhite is a rigid, opaque white, producing 20 percent more brightness and UV resistance than the current VeroWhite. And, VeroCyan has been improved with a brighter, more vibrant appearance.

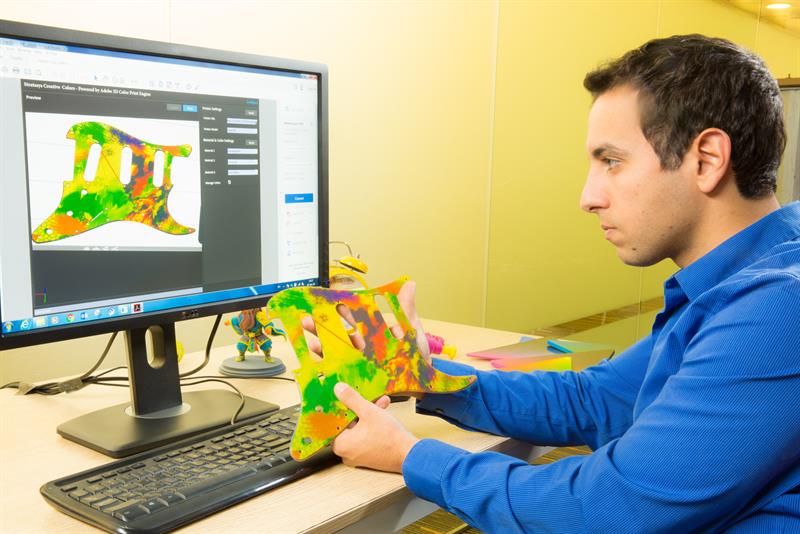

What colours you see on screen is what you will get in the printed part

What colours you see on screen is what you will get in the printed part

The Stratasys printing platform is called Connex3 and it uses a PolyJet technology that allows three materials, photopolymer based resins, to be printed at once. While this can be used to create materials with specifically tailored properties, it is also the same technology that makes the full 3D printing in colour possible. In fact the printers themselves require no changes to the hardware in order to achieve this colour capability, it is software that needs to upgraded. This will be offered in the coming months as standard on new Connex3 printers and available as an upgrade in the interim.

“It is exactly like any inkjet printer,” said Leslie Frost, marketing communications manager of Stratasys. “This machine has eight different heads, and each head has multiple microscopic nozzles that inputs droplets on the platform, just like you would with an inkjet printer.”

Each colour has two heads and two further heads print support material. A full range of colours will only be available if a five-colour (red, yellow, blue, black and white) machine is developed. Is this on the hoirizon? “I'm sure that is something that is being looked at and worked on,” said Frost. “Limiting yourself to three materials and three colours is somewhat limiting your palate.So I'm sure that something is going to come out in the future.I just don't know anything as of right now.”

For the time being, the Creative Colours software is going to change colour management for the CAD user. “What we're able to do within Adobe Photoshop is take our knowledge of how these materials combine inside the Connex3 and effectively give that information to the Photoshop user,” said Scrutton. “We can help guide and in some ways constrain their use of colour in the application so that you know that the colours you're picking are achievable on the printer with these materials.”

The new software now allows over 1000 colours to be used. Just as importantly, claimed Scrutton, there will be no surprises when the colours are printed: “We've actually taken Adobe code, Adobe technology, and put it inside [the Stratasys] printer.And the good thing about that is that it means it's exactly the same code inside Adobe Photoshop that our designers have. It's exactly the same code inside of Adobe Acrobat and Adobe Reader, which is what your clients used to preview that PDF.” In other words – what is printed out is the same as what was seen on screen.

“Everything that you normally do in Adobe Photoshop, now you can apply to 3D printed parts,” continued Scrutton. “You can pull in an image, you can do textures and different gradients and everything. So it adds a whole different layer to what the designers are going to be capable of using to design.”

Paper progress

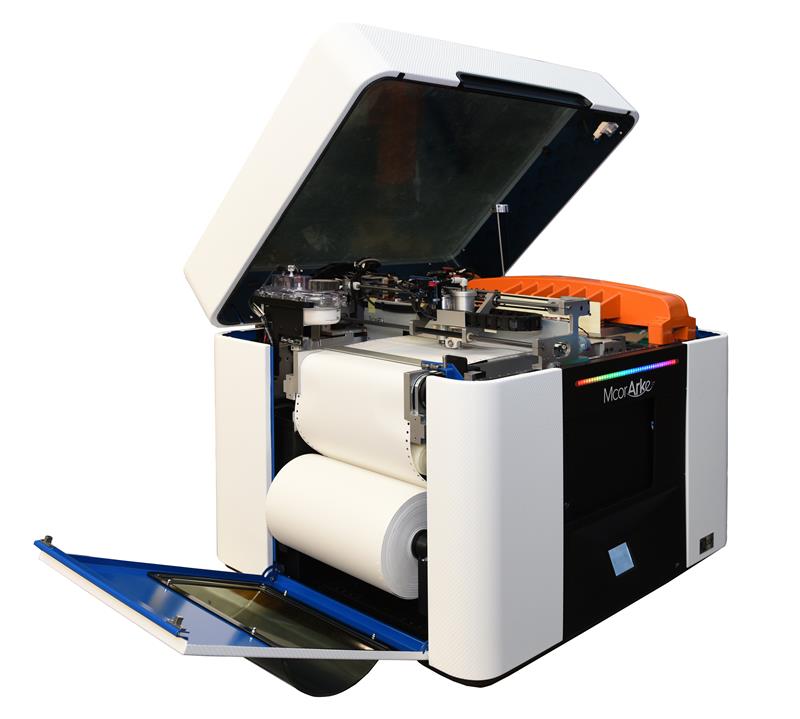

There are not many full colour solutions currently open to the 3D printing market, but one of them has been Mcor’s novel paper-based technology (see Eureka, Dec 2015 ‘Multi-coloured paper maker’). That technology has now been improved with its new printer ARKe, which is a desktop unit. It will replace the company’s existing IRIS range, offering a substantial saving in outlay (from approximately £10k down to £6200), a fourfold speed improvement and 1.5 better colour resolution. The principal difference is that in the old machine the sheets of paper were prepared separately and drawn into the machine. ARKe features a continuous roll of paper and all the preparation steps – cutting the paper and applying the adhesive, which also contains the pigment – are done in the single unit. “The idea is that the ARKe will operate just like an ordinary 2D desktop printer that can be accessed by WiFi by everyone,”said Dr. Conor MacCormack, co-founder and CEO of Mcor Technologies. “We have a bold goal – to put a 3D printer in every office, classroom, and eventually every home, and Mcor ARKe will help achieve this aspiration. A defining launch for our company, the Mcor ARKe will help designers and engineers alike bring their creative visions to life.” Acceptable file formats are STL, OBJ, VRML, DAE, 3MF. Resolution is 0.mm on all three axis, and colour resolution is ‘photorealistic HD Colour’4800 x 2400 DPI in X, Y and 254 in Z (up to 508 in Z with 50GSM paper). Moreover, the main consumable is paper, so it is a very cheap system to run. |